| MAFLA* Formation |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

*MAFLA - Mississippi,

Alabama & Florida

(Also Applicable to

East Louisiana)

Macrofractured

TMS Interval

Richland Sand Mudlog

Laminated Oil

Sand Lens in TMS

Shell Fragments

Fissile TMS Interval

Bioturbated,

Fossiliferous Marl -

Basal TMS

"Bain" Interval

Macrofracture

In TMS Core

AN UNCONVENTIONAL OIL RESOURCE PLAY THAT HAS NOT REACHED ITS FULL POTENTIAL

The oil-prone Tuscaloosa Marine Shale (“TMS”) Trend occupies an oval-shaped area that straddles the Southwest Mississippi – East Louisiana (“Florida Parishes”) area (to view a map of the Trend, please click here). To date, the Eastern "Core" Area (consisting of the Southwest Mississippi and Florida Parishes area) has proven to be the most commercially important Trend area, with producing wells having been completed in the TMS at a true vertical depth ranging approximately from 11,000 feet to 14,000 feet subsea. The Trend area is predominantly rural, consisting of farmland and pastureland, with some softwood timber cultivation. Severance tax abatements, designed as temporary incentives, exist for horizontal TMS completions in both Mississippi and Louisiana.

Historically, the geopressured TMS was first encountered in September 1950, when Humble Oil & Refining Company encountered a strong influx of oil and gas from the Marine Shale of the Middle Tuscaloosa while drilling at a depth of 11,646 feet in a Lower Tuscaloosa test well in the southwest Gillsburg Field area (#1 Stockard, 33-1N-6E) of Amite County, Mississippi, just north of the state line. The Gillsburg structure is a rare anticlinal closure in the Eastern "Core" Area of the TMS Trend. Humble set intermediate casing, changed over to oil-based mud, and cored the remainder of the TMS in the #1 Stockard before drilling the well to a total depth of 12,500 feet. The operator then plugged back to 12,052 feet and drillstem-tested an interval that included the lower portion of the TMS as well as the Lower Tuscaloosa. The well flowed "by heads" on DST, yielding about 19 barrels of light green oil (from the TMS) and considerable saltwater (from an underlying Lower Tuscaloosa sand). The well was abandoned, but the #1 Stockard became historically important as the first penetration of the geopressured TMS in what would later become known as the Eastern "Core" Area. From that point forward, as the (conventional) Lower Tuscaloosa Trend expanded into Southwest Mississippi, the TMS became a tempting exploration target for some companies (Sun, Callon) and an annoyance and potential drilling hazard for everyone else. Unfortunately for the optimists who attempted to test the interval, the few vertical completions in the TMS that were attempted over the years failed to extract more than a few barrels of oil on a daily basis, and interest in the TMS as a commercial oil resource waned.

The advent of horizontal drilling led several operators to drill short laterals into the TMS in the late 1990's, but those early laterals were not fracture-stimulated and soon declined to rates that were essentially the same as the vertical TMS completions attempted decades before (for reasons discussed further below). In the late 2000's, attempts by Encore Operating to drill "longer" (2,000' - 3,000') laterals and to frac the TMS with single-stage stimulations were somewhat encouraging, but short-lived and plagued with completion problems. The first "modern" TMS lateral successfully drilled and completed with multi-stage frac technology was the Encana Weyerhaeuser 73H-1 well, drilled in North Chipola Field in St. Helena Parish, Louisiana in the fall of 2011. The 73H-1 lateral, drilled after a pilot hole had cored much of the TMS, bottomed at a measured depth of 18,164' (TVD 12,662') in sidetracked hole after drilling a 6,117' lateral in the lower TMS. Following a 17-stage frac that utilized 4,255,040 lbs. of proppant, the 73H-1 well officially reported an initial potential of 280 BOPD + 98 MCFGPD. However, in its first full month of production (December 2011), the well produced 18,036 BO and 7,445 MCFG, a daily rate of approximately 600 BOPD + 248 MCFGPD. This more impressive sustained monthly production rate, along with high oil prices, ignited the TMS Trend, which remained quite active until the downturn in oil prices began in the fall of 2014. Ironically, the 73H-1 lateral is also distinguished as the first TMS lateral to exhibit the production of extraneous saltwater from sandstones in the underlying Lower Tuscaloosa, which had been unintentionally fractured into during the original fracture stimulation. Drilling activity in the Trend essentially ceased by the summer of 2015 and all of the original TMS operators left the Trend by the end of 2016.

Encana, the dominant TMS player, eventually sold its holdings to Australis TMS, which drilled six new TMS laterals during 2018-2019. Of those four wells, two (Stewart 30H; Taylor 27H-1) appear to have been commercial completions, while the other four were sub-commercial. As of April 2024, the Stewart 30H had produced 337,849 BO + 276,782 BW + 130,560 MCFG (359,609 BOE) in 64 months, while the Taylor 27H-1 had produced 224,439 BO + 119,347 BW + 112,363 MCFG (243,166 BOE) in 59 months. This geologist served as the wellsite geologist for several of these recent TMS laterals drilled by Australis, including the best well, the Stewart 30H. By the winter of 2019, Australis' six-well drilling program had run its course, and the Trend had once again grown quiet.

In November of 2021, a newcomer to the Trend, State Line Exploration, spudded the Reese 11 #1H in southern Amite County, Mississippi, not far from several TMS laterals drilled earlier by Encana. The Reese TMS lateral (MD 19,087'; TVD 12,489') was completed in February of 2022 with an initial potential of 1,801 BOPD + 500 MCFGPD + 1,650 BWPD (presumably frac water flowback). The completion of this lateral was different than most TMS completions in that the well was placed on pump immediately after its initial test. As of April 2024 (the most recent month of production reported to the State O&G Board at the time of this report), the Reese well had produced 129,433 BO + 147,191 BW + 111,812 MCFG (148,068 BOE in 27 months; 87.4% oil) and was averaging 71 BOPD + 55 BWPD + 17 MCFGPD. It appears monthly oil production peaked in March 2022, when the Reese TMS lateral produced 13,799 barrels of oil for a 25-day average of 552 BOPD.

Here are some highlights from the recent drilling of lateral wellbores within the TMS Trend:

First TMS lateral drilled - Louisiana: UPRC #5-1 Richland Plantation (STH #2) (East Feliciana Parish, Louisiana) (1998; effective lateral length 1,100'; not frac'd)

First TMS lateral drilled - Mississippi: Worldwide Cos. #1 Braswell 24-12 (Pike County, Mississippi) (1998; effective lateral length 1,419'; not frac'd)

Longest lateral drilled to date: Encana Lawson 25-13 H-1 (Amite County, Mississippi), 9,798 feet

Highest number of stages fractured: Encana Anderson 17H #3 (Amite County, Mississippi), 32 stages

Largest total proppant load pumped: Encana Lawson 25-13 H-1 (Amite County, Mississippi), 23,517,130 lbs.

Highest average proppant load per stage pumped: Encana Ash 31H-2 (Amite County, Mississippi), 923,612 lbs. / stage (ironically, the Ash 31H-2 has been one of the poorest performing wells completed by Encana; as of April 2024, the 31H-2 well had produced only 152,691 BOE in 115 months)

Highest reported 24-hour Initial Potential ("IP24"): Encana Longleaf 29H #2 (Amite County, Mississippi), 1,915 BOEPD

Highest reported 30-day Initial Potential ("IP30"): Encana Longleaf 29H #2 (Amite County, Mississippi), 38,672 BOEPD, Average 1,289 BOEPD

Highest Cumulative Production as of April 2024*: Encana Longleaf 29H #2 (Amite County, Mississippi): 724,053 BO + 217,051 BW + 378,974 MCFG (787,215 BOE in 109 months (92% oil); as of April 2024*, the 29H #2 was still producing at the rate of ~101 BOEPD (86 BOPD + 19 BWPD + 91 MCFGPD), and had produced 110 BOE/ft of lateral length). The Longleaf 29H #2, a toe-down lateral, had an effective lateral length of 7,138' and was fracture stimulated over 20 stages. Here are the statistics pertaining to the 29H #2 fracture stimulation. Total proppant pumped: 11,184,000 lbs. (1,567 lbs/ft); total fluid pumped: 236,279 barrels (1,390 gal/ft); clusters per stage: 5; holes per cluster: 7; average cluster spacing: 71 feet; average proppant load per cluster: 111,839 lbs. (approximately 559,195 lbs. / stage); average fluid volume / cluster: 2,363 bbls. Produced water as of April 2024* represented 80% of water injected during fracture stimulation.

Other wells of note (cumulative production as of April 2024*): the Encana Lawson 25-13 H-1 (Amite County, Mississippi) has produced 568,050 BO + 479,308 BW + 258,325 MCFG (611,104 BOE in 110 months (93% oil); as of April 2024*, the Lawson 25-13 H-1 was still producing at the rate of ~54 BOEPD); the Encana Mathis 29-17H (Amite County, Mississippi) has produced 415,851 BO + 270,653 BW + 211,492 MCFG (451,100 BOE in 111 months; as of April 2024*, the Mathis 29-17H was still producing at the rate of ~45 BOEPD); and the Encana Mcintosh 15-H #1 (Amite County, Mississippi) has produced 378,335 BO + 469,957 BW + 379,681 MCFG (441,615 BOE in 109 months; as of April 2024*, the McIntosh 15-H #1 was still producing at the rate of ~44 BOEPD).

One of the gassier TMS completions, the Encana Ash 13H #1 (Amite County, Mississippi) has produced 424,639 BO + 1,163,472 BW + 987,869 MCFG (589,284 BOE in 109 months (72.1% oil); as of April 2024*, the Ash 13H #1 was still producing at the rate of ~87 BOEPD (65.3% oil). This geologist suspects that the Ash 13H #1 well frac'd into both a Lower Tuscaloosa hydrocarbon-bearing reservoir and a Lower Tuscaloosa saltwater-bearing reservoir (which would not be difficult to do, since the Lower Tuscaloosa "A" Sand is only ~30 feet beneath the base of the Bain / TMS, and the underlying Lower Tuscaloosa "B" Sand - almost always saltwater-bearing - is only ~60-70 feet beneath the base of the Bain / TMS. If one examines the cumulative production for the Ash 13H #1 well (as of April 2024), the volume of produced gas (987,869 MCFG) is anomalously high, and so is the volume of produced water (1,163,472 BW, which is 301% of the total volume of water injected during the fracture stimulation). This strongly suggests the extraneous contribution of gas, saltwater and almost certainly oil from one or more underlying Lower Tuscaloosa reservoirs. This fracture communication with the Lower Tuscaloosa could have easily been avoided (see comments below).

* Latest production reported to the State as of April 2024 (two to three-month lag in reporting)

How do these TMS wells compare to the per-well production statisitics of the largest unconventional oil resource plays in the United States (Permian, Bakken, Eagleford)?

The following statistics, aggregated by Shale Profile Analytics, were recently published online by the Journal of Petroleum Technology ("Life After 5: How Tight-Oil Wells Grow Old"). At their 5-year (60 month) producing anniversary, horizontal wells in the Permian exhibit decline rates that fall to an average of 16.7% and will produce just under or about 30 BOPD (Permian wells completed since 2014 average ~148,000 barrels in cumulative production at their 5-year anniversary). The average 5 year-old horizontal well in the Williston Basin, which encompasses the Bakken and Three Forks shales, shows an annual decline rate of 17%. These Williston Basin laterals average 49 BOPD — the highest such figure of the three major tight-oil plays (Bakken wells completed since 2014 average ~194,000 barrels in cumulative production at their 5-year anniversary). The average decline rate of horizontal wells in the Eagle Ford Shale at age 5 is about 23.5% — the highest such figure of the three major onshore oil plays in the US. At age 5, the average well in the Eagleford play produces 28 BOPD (Eagleford wells completed since 2014 average ~171,000 barrels in cumulative production at their 5-year anniversary).

Taking these statistics into account, it would appear the 5-year decline and production rates of most TMS laterals completed since 2014 are at least as good if not better than their Permian, Bakken, or Eagleford counterparts. Yet this geologist contends the manner in which such post-2014 TMS laterals had been completed remains far from optimal.

A majority of TMS laterals drilled to date have been drilled "toe up", i.e, in an updip direction, sub-parallel to structural dip (which is generally south-southwest). The presumed advantage of drilling "toe up" is that one can take advantage of gravity drainage to aid in the production of oil from the lateral, especially later in its productive life. Unfortunately, the logic of drilling "toe up" wells is compromised when a TMS operator lands its laterals in the lowermost portion of the TMS (as will be discussed later in this report), and fractures downward into the saltwater-bearing sandstones of the Lower Tuscaloosa. When that occurs, extraneous saltwater collects in the "heel" of the lateral, severely impacting producibility and increasing operating cost. To view a recent chart of the monthly production for the Encana Ash 13H #1, an example of a toe-up TMS lateral that appears to be plagued with extraneous saltwater production, please click here.

Within the Eastern Core Area Trend, the "fissile" TMS is a grey-black, highly laminated, moderately calcareous, microfractured marine shale with primary porosity ranging from 2% to 4% and average permeability less than .02 millidarcies (see the slabbed core photograph, left). Commonly interspersed within the fissile shale in certain areas are numerous thin to wafer-thin sandstones and siltstones. These interlaminated siliciclastic zones can be cross-bedded and fractured, and in certain areas, can develop into thicker and more coarse-grained, glauconitic and chloritic clastic lenses with significantly higher porosities (as high as 8%). Analysis of the fissile TMS lithology indicates a general composition of 15–20% quartz and 40–50% clay with minor amounts of calcite, chlorite, feldspar and pyrite.

At the base of the "fissile" TMS (the actual hydrocarbon reservoir) lies a highly bioturbated, more calcareous and fossiliferous unit that is informally labeled the “Bain” or “Pilot Lime” interval (see the slabbed core photograph at lower left). The Bain interval, typically 25-30 feet in thickness, becomes more calcareous downdip, but even in the Southwest Mississippi area it is very hard with a compressive strength that is much higher (up to 300% greater) than the more fissile, overlying TMS interval. This is advantageous because the Bain interval can serve as a confining zone that limits the downward propagation of frac energy. This in turn maximizes the fracture stimulation of the overlying fissile TMS, while minimizing the possibility of fracturing unintentionally into an underlying saltwater-bearing Lower Tuscaloosa sandstone.

At the very top of the Bain interval lies the Richland Sand, a thin sandstone deposited over a substantial part of the Eastern "Core" Area. The Richland Sand is typically 4-8 feet thick and poor in porosity and permeability (see the slabbed core photograph at left, or click here to view a larger core image). However, in certain key areas, it is clear that the Richland Sand harbors appreciable porosity and permeability and is saturated with oil and gas (click here to view a mudlog example). In those key areas, the Richland Sand serves as a key "storage" component of the TMS, and in unconventional oil trends like the TMS, storage is key to commercial oil production (organic tracers have confirmed the contribution of oil from the Richland Sand in recently-drilled TMS laterals, and several wells have encountered porous, unconsolidated sand in cuttings from the Richland Sand interval; to view an example, click here). The Richland Sand cannot be detected using the spontaneous potential (SP) curve, because it presents no SP contrast with the surrounding marls and shale. However, the Richland Sand is readily mapped using the gamma ray curve. Cores and gamma ray logs indicate the TMS contains several clastic fairways that harbor most of the primary porosity storage developed within the interval. The deposition of the Richland Sand appears to be associated with a regressive pulse of clastics that heralded the end of the Bain depositional sequence; some have suggested that the Richland Sand is a hypopycnal plume deposit, which is an intriguing hypothesis. There appears to be two updip sources of the clastics deposited within the TMS: a northeast Appalachian source, and a northwest Mississippi Embayment Source. While most of the Eastern "Core" Area appears to have been sourced by the Appalachians, the Embayment source appears to furnish the clastics encountered in the area proximal to the Mississippi River. In general, the updip Eastern "Core" Area is more clastic-rich than the downdip, more distal Florida Parishes area (to view a slabbed core example from the clastic-rich updip area, click here; to view a slabbed core example from the clastic-poor downdip area, click here; and to visually compare both examples simultaneously, click here.)

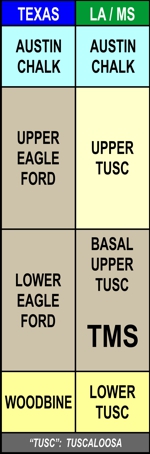

The highly resistive TMS facies thins laterally from a maximum thickness in excess of 200 feet (in the Eastern "Core" Area) to less than 30 feet of thickness in the west-central Louisiana area. A similar loss of highly resistive shale occurs to the north and east as shown on the TMS Trend Map. To the south, structural dip steepens south of the Lower Cretaceous (Edwards) Shelf, and the TMS plunges to depths deeper than 17,000 feet before becoming downthrown south of the first large down-to-the coast faults that cut the interval in the Baton Rouge area. Deep Lower Tuscaloosa wells drilled in that area confirm the transition of the TMS hydrocarbon “windows” from oil to dry gas, with a narrow wet gas (condensate) window interpreted in the deeper southern portions of the Florida Parishes, just north of the Deep Lower Tuscaloosa Trend. The Tuscaloosa Formation represents a complete depositional cycle of marine regression and transgression. Prior to the deposition of the basal Lower Tuscaloosa, sea level fell and the entire Gulf Coast was extensively eroded. The erosional surface at the base of the Lower Tuscaloosa represents the major unconformity that demarcates the Upper Cretaceous / Lower Cretaceous boundary. For more information regarding the Lower Tuscaloosa, please click here.

In certain areas, it has been observed that a strong influx of oil and gas occurs high above the "traditional" top of the TMS. The onset of this influx (gas kicks, oil “on the pits”) tended to be associated with the initial drilling of one or more basal Upper Tuscaloosa sandstones or siltstones encountered approximately 150-200 feet above the top of the high-resistive TMS. In some instances the strength and quality of the oil and gas show across the basal Upper Tuscaloosa (nicknamed the "EagleTusc" by this geologist) was much more intense than that of the underlying TMS.

The high-resistivity, "traditional" TMS is directly overlain by the marine shales, silts and sandstones of the basal Upper Tuscaloosa (EagleTusc) Formation, which is the time-stratigraphic equivalent of the Middle Eagle Ford in Texas. While the marine shales of the EagleTusc are thinner and somewhat less calcareous than their underlying TMS counterparts, the interval is still brittle and easily fractured, and the clastic content is generally much greater. It is clear that, because of its proximity to the TMS, in those areas where the EagleTusc is heavily fractured, its sandstones and siltstones have become highly charged with TMS-sourced oil and gas, at equivalent (abnormally high) pressures; and the combined interval is both fracture and pressure-interconnected. The EagleTusc clastic units thus contribute substantial additional hydrocarbon “storage” capacity to the combined TMS / EagleTusc interval, which doubles in gross thickness when compared to just the highly-resistive TMS interval. Log analysis indicates that EagleTusc clastics generally average 4% to 9% porosity, exhibit moderately high e-log resistivity, and are highly laminated. The thicker clastic units can exceed 40 feet in gross thickness and are easily correlated across the subject area, implying significant reservoir volume. It appears that those EagleTusc intervals that exhibit resistivities in excess of 2 ohm-meters contain high clastic concentrations and represent potential hydrocarbon reservoirs. The principle of mechanical stratigraphy best describes the preferential fracturing of the hard, brittle EagleTusc sandstones and siltstones that are interlaminated between more ductile EagleTusc shales; to view a classic example of mechanical stratigraphy, please click here.

Many geologists consider the Texas Pacific #1 Winnie Blades (completed May 26, 1978; 42-1S-8E, northern Tangipahoa Parish, Louisiana) to be an important vertical legacy well for the TMS, in that it had reputedly produced oil from the "TMS" for several decades. What most geologists do not realize is the #1 Blades was actually completed across a ~600' interval that was comprised of not only the "traditional" TMS interval, but also the overlying EagleTusc interval. In fact, more intervals were perforated within the EagleTusc than in the "traditional" TMS in the #1 Winnie Blades "TMS" completion. (This was because of the good mudlog oil and gas shows that had been observed across the subsequently-perforated EagleTusc intervals, well above the top of the "traditional" TMS.) When Encana petitioned the Mississippi Oil & Gas Board for Special Field Rules for its TMS oil fields in Southwest Mississippi, it expanded the definition of the "TMS" to specifically include virtually all of the stratigraphic equivalent of the overlying EagleTusc. To view the #1 Winnie Blades "Type Log", and the stratigraphic relationship of the TMS and overlying EagleTusc, click here.

Geopressure within the TMS is confined to open fractures and permeable clastic intervals. Where the matrix is virtually 100% shale, the interval is impermeable, and the matrix of such shale is not geopressured. The system of microfractures within much of the TMS (created by the cracking of oil to gas following generation) collapses within a radius around a TMS producing wellbore as hydrocarbons are removed (and pressure diminishes) via drilling or production. Mudlog shows are attributable to gas and oil liberated when a cylindrical volume of the microfractured TMS is drilled up by the bit. In most cases, this influx diminishes significantly as the microfractures around wellbore are de-gassed and collapse. Contrary to what has been claimed in the past, there are no verifiable instances of loss of control ("blowouts", etc.) attributable to the uncontrollable influx of oil and gas from the shale intervals within the fissile TMS; virtually all such incidents are actually associated with the influx of geopressured hydrocarbons from clastic units within the overlying EagleTusc or developed at the very top of the TMS (i.e., atop the fissile TMS shale). Ironically, most thin clastic intervals that contribute such strong oil and gas shows at the very top of the highly-resistive (fissile) TMS interval exhibit a resistivity profile that is less than 4 ohm-meters; accordingly, such important hydrocarbon-bearing clastic intervals aren't even included in many explorers' so-called "net pay" isoliths.

Vertical wells drilled through the TMS typically de-gas the shale around the wellbore within 12-24 hours of drilling the interval, which is usually less than 150 feet in thickness. This permits drilling to continue with mudweights only slightly elevated above the "normal" (Gulf Coast brine-filled) pore pressure gradient. Hundreds of (vertical) Lower Tuscaloosa wells have been successfully cored and logged after drilling through and controlling the TMS with mudweights of less than 10 PPG. However, a TMS lateral continues to drill (as intended) through the geopressured, fractured TMS interval over an interval that may exceed 9,000', and the mudweight typically required to control the lateral wellbore and keep it from collapsing is approximately 13 PPG. The geopressure gradient within the TMS ranges from 0.50 psi/ft. in the northern (presumably non-commercial) part of the Trend to 0.75 psi/ft. in the downdip Florida Parishes area. In the heart of the Eastern "Core" Area, the geopressure gradient within the TMS fracture systems averages 0.65 psi/ft (the "normal" Gulf Coast pressure gradient for saltwater (with 100,000 ppm total dissolved solids) is 0.465 psi/ft.). The frac gradient for most of the frac stimulations in the Eastern "Core" Trend typically averages 0.95 psi/ft to 1.05 psi/ft.

An excellent example of the de-gassing of TMS microfractures in a vertical TMS penetration is the post-drilling well flow test conducted in a TMS vertical wellbore drilled recently in eastern Wilkinson County, Mississippi. This well is now surrounded by lateral TMS producers that required ~13 PPG mudweight to drill and control each lateral wellbore. In the vertical TMS wellbore, after coring and logging operations had been completed, to determine the flow potential of the open TMS interval, the operator injected nitrogen into the mud system to temporarily lower the density of the drilling mud and thus lower the hydrostatic pressure in the wellbore to an equivalent ECD ("Equivalent Circulating Density") of only 7.8 PPG. The well had been drilled underbalanced with oil-based mud, and there was no significant mud loss to the formation. The influx of oil and gas from the TMS that had occurred during the drilling stage had virtually ceased by the time the nitrogen-cut well flow test was conducted, a few days later. The microfracture system encountered by the wellbore had de-gassed and essentially collapsed around the wellbore.

The pervasive microfracturing of the TMS has been enhanced in certain areas by the drape of the TMS over underlying structures and regional flexures (dip/slope changes), which created sub-regional fracture swarms that augmented the microfracture system. Fracture swarm orientation is generally “strike” (NW-SE) oriented, but may vary locally in such “enhanced fracture” areas. Knowledge of the location and extent of these enhanced fracture areas, and clastics content and distribution, aids in targeting potential “sweet spots” in the Trend, where storage was optimal. Click here to view an illustration of enhanced fracturing caused by differential compaction over the underlying Lower Tuscaloosa "A" Sand, when present; to view a similar illustration of enhanced fracturing caused by a dip/slope change or drape over a deep-seated structure (like the Gillsburg Structure), please click here.

Because the geopressured (oil and) gas that microfractured the fisslie TMS shale is the only force holding those microfractures open, draining the oil and gas from (and thus lowering the geopressure holding open) those microfractures causes them to collapse (close), dramatically and permanently impacting the producibility of a TMS wellbore. Injecting large volumes of proppant into the microfracture shale temporarily alleviates the problem by propping open some of the microfractures in the stimulated area, but it is clear that the best production is going to be derived from areas where a frac’d TMS lateral accesses not only the microfracture system but also the larger sub-regional macrofracture swarms and the porous and permeable, oil-saturated clastic lenses within the TMS (that tend not to collapse when drained). Already, certain TMS wells are clearly outperforming the average TMS decline curve, and this geologist believes those better wells have accessed nearby areas of enhanced storage - the much sought-after "sweet spots" in the Trend.

Conversely, it is important to understand this corollary: a TMS wellbore that only encounters (and fracture stimulates) the ubiquitous microfracture system within the TMS will not, at current commodity prices, drain a commercial volume of oil and gas from the TMS. Additional storage must be accessed. This important observation is intended to serve as a cautionary advisory to those who would like to believe (or represent) that one can simply drill anywhere in the Eastern "Core" TMS Trend Area and complete a commercially successful TMS producer. That having been said, it is also important to understand that the sub-regional macrofracture swarms and oil-saturated clastic lenses developed within the fissile TMS interval are quite common and readily targeted by those who have mapped the Trend and identified such significant areas of enhanced storage. It would appear hundreds of new, optimally-completed TMS laterals will need to be drilled to efficiently drain the enhanced storage areas / sweet spots of the Eastern "Core" TMS Trend Area.

Relatively few TMS pilot (vertical) wells have been drilled by the companies that have recently drilled long lateral wells in the TMS. This means that the most of the well data needed to understand the TMS Trend on as regional basis has been that data contributed by the abundant "legacy" vertical wells drilled in the area (which had principally targeted the underlying Lower Tuscaloosa Stringer Sands). This geologist has worked the Lower Tuscaloosa Trend since 1981 and was a wellsite geologist responsible for coring and logging numerous Lower Tuscaloosa legacy wells within what would later be characterized as the Eastern "Core" Area of the TMS. In addition, Vision Exploration served as geological consultant for two of the most active TMS operators from 2011-2019, and managed substantial TMS leasing programs for two investor groups from 2008 to 2015; as such, Vision has been directly involved in geological, geophysical and leasing operations in the Eastern Core Area of the TMS since the very beginning of the play. This unique combination of 39 years of Tuscaloosa / TMS Trend experience and direct involvement in such recent TMS operations clearly sets Vision apart from most independent consulting groups that claim to have experience in the Trend, which is important because much of the information that has been previously published about the TMS is - in this geologist's opinion - incomplete, misleading, or simply inaccurate.

For example, it has been claimed that the Passey Log Analysis Method can be accurately utilized to identify and calculate Total Organic Carbon ("TOC") in the legacy Lower Tuscaloosa penetrations within the TMS Trend, by overlaying the sonic transit time curve on the deep induction resistivity curve; hydrocarbon-bearing or organic-rich rocks could then be identified by observing those intervals where separation between the sonic and resistivity curves is observed. The gamma-ray curve is also used as a discriminator, but the reliance upon the sonic curve as the key porosity curve is a critical and integral component of the Passey Method as employed in the log analysis of the legacy wells drilled within the "Eastern Core Area" of the TMS.

Unfortunately, regardless of whether one agrees with the efficacy of the Passey Method, one cannot utilize sonic curve data across an interval where the wellbore is washed out. A washed-out ("rugose") wellbore cannot be accurately logged with a sonic tool. This is a basic tenet of petrophysical analysis. Virtually every legacy Lower Tuscaloosa wellbore drilled in the TMS Trend was severely washed out across the TMS interval when logged. This was principally the consequence of (1) drilling the TMS with a high water-loss, water-based drilling fluid; (2) diamond coring operations frequently conducted just below the TMS (across the Lower Tuscaloosa "A" Sand), which were often lengthy and required considerable reaming of the hole both before and after such coring attempts; and (3) more reaming and hole conditioning that followed once the well had been drilled to total depth and prepared for open-hole logging.

A sonic log run across a washed-out TMS interval will obviously yield an erroneous (slow) acoustic travel time, because the rugose hole is filled with drilling fluid, which is not nearly as dense as the fissile TMS matrix. Such sonic travel times are worthless and should not be used in any petrophysical calculations, including the Passey Method. For this reason, it is critically important that the caliper or differential caliper curve be presented (displayed) whenever porosity log curves - and especially sonic log curves - are presented. If the caliper or differential caliper curve is not presented or not available, the use of the sonic curve should be automatically called into question, and until rugosity is ruled out, any resulting sonic log analysis must be invalidated. To view an example of a legacy Lower Tuscaloosa wellbore drilled in the Eastern "Core" Area that was severely washed out across the TMS interval, click here.

Yet this geologist has witnessed numerous TMS "Passey" log analysis displays where the caliper or differential caliper curve was not presented. In virtually every such presentation, this geologist has immediately recognized the sonic log that was used in the analysis to be invalid across the TMS because of severe hole rugosity. It is unfortunate that such data is presented as valid petrophysical data. It is not. With very rare exceptions, the only wellbores that are not washed out across most of the TMS interval are those wellbores that have been carefully drilled with oil-based mud (and only a few recently-drilled wells meet this criterion).

An example of this issue is the dual induction / sonic log for the Coastal #1 Wall 15-13 (Section 15-1N-5E, Amite County, Mississippi), the legacy Type Log for the Alfred C. Moore and Pearl River Fields; inexplicably, when the #1 Wall was logged, the operator (Coastal) allowed the dual induction / sonic log raster to be generated without the presentation of the critically-important caliper curve. This renders that Type Log unusable for Passey Method analysis. Yet this geologist has witnessed the Passey Method analysis conducted using the same compromised log. This is untenable.

Having reviewed the porosity logs run across the TMS in those few wellbores that are not washed out across most of the TMS interval (most all of which were recently-drilled TMS "pilot" holes), this geologist has concluded there is negligible Passey separation or correlation with TOC. Accordingly, it appears that the Passey Method is neither a useful nor an accurate petrophysical method for analyzing vertical legacy wells drilled in the TMS Trend. Many "Shale Oil Advisor" logs have also failed to correlate accurately with the lithology, clay minerology, and TOC obtained from cores cut across the TMS in the same wells; for example, this geologist has observed Shale Oil Advisor logs generated from wells drilled in the downdip distal Trend to indicate very sandy intervals within the TMS were penetrated, while the diamond cores cut across the same interval yielded virtually 100% shale with nil laminated sand or silt. This suggests that much modeling work remains to be done before such "advisor" logs can be trusted to yield reliably accurate and correlative results in the absence of diamond cores.

The "traditional" TMS interval is commonly associated with increased resistivity in the Middle Tuscaloosa Marine Shale interval, and many geologists use an arbitrary resistivity cut-off of 4 ohm-meters in mapping the prospective area within the Trend. Resistivity is a function of lithology (changes in the calcium content of strata) within the TMS, and has nothing to do whatsoever with the presence (or absence) of hydrocarbons. In fact, the most highly resistive intervals within the TMS are almost always the least porous and permeable, and contain the lowest TOC. The highest resistivity in the TMS Trend is associated with areas where the TMS lithology has transitioned to a marl or cryptocrystalline limestone (in the southern, more distal portion of the Trend). While higher resistivity can be directly associated with harder, more brittle (and more calcareous) TMS facies, high resistivity cannot be quantitatively associated with the presence, volume, or recovery of hydrocarbons. Any attempt to directly associate the thickness of highly resistive TMS strata with hydrocarbon volume or recovery is fatally flawed. The best utility of mapping TMS resistivity is for locating the thickest areas of brittle TMS rock; one must then attempt to search for areas of optimal storage (enhanced fracture areas, porous clastics) developed within that thicker, highly-resistive, brittle rock interval.

Inexplicably, even though the fissile, highly-prospective "traditional" TMS interval is typically over 130'-140' in thickness, many TMS operators have chosen to land their TMS laterals within the 30 foot-thick Bain interval located at the very base of the TMS, literally 15 feet (or less) from the base of the TMS. The Bain interval is the most calcareous, hard, and brittle interval within the TMS. It grades lithologically from a nonporous bioturbated marl in the Southwest Mississippi area to a relatively pure (and nonporous) shallow marine limestone in the downdip southern Florida Parishes area of Louisiana, where it was nicknamed the "Pilot Lime" by geologists targeting the underlying Deep Lower Tuscaloosa Trend. In much of the Eastern "Core" Area, the Bain can be further subdivided into three distinct units, each typically 10' thick: the Upper Bain, a highly-bioturbated micaceous limestone that hosts the Richland Sand interval at the top of the unit; the Middle Bain, which is much more shaley (and often, pyritic), and contains the only appreciable TOC within the Bain interval; and the Lower Bain, which is the most calcareous, densest and least porous unit, frequently comprised of cryptocrystalline limestone.

It should also be pointed out that there have been numerous instances where, in the course of attempting to land their laterals in the Middle Bain interval, operators frequently failed to stay "in zone" and drilled beneath the base of the Bain (the TMS) into the underlying Lower Tuscaloosa Formation, even closer to the (frequently saltwater-bearing) sandstones just 10 to 20 feet further downhole. In some instances, such "out of zone" excursions have been minimal; in others, the bit strayed below the TMS for a considerable depth and distance. It remains a challenge to stay within such a narrow target while routinely drilling laterals in one of the deepest unconventional resource plays in the country.

By conducting massive fracture stimulations of their laterals landed in

the (preferably Middle) Bain interval, TMS operators have undoubtedly frac'd into the

underlying

saltwater-bearing sandstones of the Lower Tuscaloosa, which

can be developed less than 30 feet below the base of the TMS (TMS

frac half-heights for 400,000 lb. frac stages have been calculated as

extending downward 200 feet or more). Many TMS completions

are only now manifesting the influx of large volumes of extraneous brine

from the Lower Tuscaloosa. An unfortunate example is the very

first TMS well that was frac'd with a "modern" multi-stage stimulation,

the

Encana Weyerhaeuser 73H-1;

this well has produced significant volumes of extraneous brine,

yet the proppant

loads pumped away in its "modest" fracture stimulation were only half the size of

average proppant loads pumped just two years later. Because the

underlying saltwater-bearing sandstones of the Lower Tuscaloosa are

normally pressured, significant production of the extraneous Lower

Tuscaloosa brine will not occur until the higher reservoir pressure of

the TMS declines to an equivalent of the Lower Tuscaloosa pressure.

For this reason, serious issues with extraneous water production will

typically not be manifested until the TMS lateral has been in

production for approximately a year, if not longer.

The compressive strength of the Upper and Lower Bain intervals is

roughly

300% greater than that

of the overlying

fissile, microfractured, hydrocarbon-bearing TMS. As is the case

with many shales, the fissile TMS

interval, which harbors >95% of all of the hydrocarbons trapped within

the TMS, is

horizontally / laterally weak (along the bedding planes), and proppant pumped into the fissile TMS will

propagate much further laterally than proppant pumped into the

non-fissile, much harder Bain interval.

Since the stated intent of TMS operators is to drill wells into the most

productive intervals of the TMS, and to propagate as much proppant as

possible into the targeted source rock, one would think that those operators would focus their

drilling and completion efforts on the fissile, microfractured,

hydrocarbon-bearing TMS. But that is often not the case.

Some operators have described a so-called "rubble zone" to exist within the lower fissile TMS, just above the Bain interval. The use of this term arose when an operator suffered parted production casing in the "turn" of a TMS lateral, at a hole angle of approximately 72 degrees (an interval of maximum tensile stress), and blamed it on the reservoir (even though the subject lateral had been drilled and cased to total depth - and frac'd - without any issues whatsoever). The assertion was that there is an interval of unstable geopressured rubble (loose rock) in the TMS. No such interval exists; this interval has been extensively cored and drilled, and is lithologically similar to the rest of the overlying fissile shale interval, but it (like the overlying fissile interval) is certainly more microfractured than the underlying Bain interval. To view a core cut across the so-called "rubble zone" in a key TMS pilot hole (in the heart of the Eastern "Core" Trend), click here. Casing deformation and parted casing has occasionally been blamed on the so-called rubble zone, but the reservoir is not the issue (recall that the shale of the fissile TMS itself is not geopressured; the pressure is constrained to the open fractures and porous clastics). What isn't routinely discussed is the fact that virtually all of the recent TMS laterals were drilled during recent "boom times" for the unconventional oil trends in the United States, and 39 years of experience with other "boom and bust" cycles has demonstrated to this geologist that mechanical issues attributable to substandard casing and inexperienced drilling and casing crews are very common during such "boom" times, and the principal cause of the vast majority of such mechanical failures - regardless of whether those failures occur onshore, or offshore. While it may be tempting to blame the reservoir, the use of poorly inspected substandard casing or other faulty equipment - or the increased stress induced when an operator attempts to run production casing through an interval where poor geosteering led to the drilling of an undulating "crooked" hole - are the actual reason for parted or deformed casing. Other common issues include the imprudent use of a "hole opener" after the lateral has been drilled, when a conditioning trip with a less stiff (and slightly smaller outer diameter) bottom-hole assembly would have sufficed to prepare a TMS lateral for a successful production casing run. There are many examples of TMS laterals having to be redrilled or undergo extensive (and expensive) fishing operations after a hole opener bottom-hole assembly became stuck in the lateral wellbore.

Ironically, the stated purpose of the drilling of unconventional, frac'd laterals is the intended rubblization of an otherwise "tight" source rock via fracture stimulation. Because of the geopressure associated with open fractures in the fissile TMS, intervals of optimal fracturing (the important macrofracture swarms) within the TMS can be more challenging to drill, but they should not be avoided; they should be deliberately targeted by the bit. Unfortunately, historical drilling data collected from 2011 to 2019 has demonstrated that many TMS operators still lack the expertise or the willingness to drill such challenging intervals. The notion that landing a TMS lateral in the underlying Bain interval is more prudent has been demonstrated to be flawed, and the threats of drilling "out of zone" beneath the Bain or encountering bit-destroying, heavily pyritic intervals within the Bain are very real.

As is the case with all unconventional resource plays, proper "parent-child lateral wellbore spacing" (i.e., the most efficient spacing for TMS laterals) is a point of concern for operators seeking to efficiently develop and drain their TMS properties. While there has not been a lot of research conducted on fracture propagation and actual frac heights, there is a modicum of microseismic data that suggests a typical "modern" TMS fracture stimulation in the heart of the Eastern Core TMS Area could generate fractures that extend as far as 1,000' from the wellbore with average frac half-heights that range from 150' above the wellbore to over 250' below the wellbore. There are many variables that could significantly impact these good-faith estimates, but clearly, if a TMS lateral lands in the middle of the Bain interval (thus compromising its efficacy as a frac barrier), the risk of fracturing downward into the underlying Lower Tuscaloosa saltwater-bearing sands (located as close as only 30 feet below the base of the TMS / Bain interval) is very high.

The TMS Trend is one of the deepest and most challenging unconventional oil trends in the United States. It remains poorly understood and, in the opinion of this geologist, suffers from a lack of understanding and questionable technical assumptions regarding its lithology, prospective intervals, storage capacity, and producibility. As this geologist had predicted in 2011, certain areas previously identified within the Eastern "Core" TMS Trend are now emerging as commercially important "sweet spots"; the identification and exploitation of these TMS sweet spots will remain critically important as the current Trend production matures during a period of moderately low commodity prices and minimal new drilling activity.

Steve Walkinshaw, P.G.

President, Vision Exploration

This report is intended to comprise a brief geological summary of the TMS Trend, and reflects the technical observations and professional opinions of Vision Exploration, LLC; if your company is interested in the Trend, and you would like to learn more about the TMS, or wish to take advantage of our Trend experience and technical expertise, please feel free to contact us. Please take the time to read our Disclaimer.

This entire site Copyright © 2024. All rights reserved.