THE MOST IMPORTANT SANDSTONE RESERVOIR IN THE BLACK WARRIOR BASIN

Use the Black Warrior Basin geology links below or the Interior Salt Basin geology links in the left column to navigate to different geologic topics.

|

|

|

|

|

|

|

The Carter Sand is the most important producing reservoir of the Upper Mississippian Parkwood Formation in the Black Warrior Basin. The Carter Sand and the underlying Sanders Sand represent a clastic wedge that in northwest Alabama is bracketed between the Millerella Limestone (above) and the Bangor Limestone (below); the Bangor Limestone also serves to demarcate the Upper Mississippian Parkwood Formation from the Lower Mississippian Floyd Shale (in Alabama; the Bangor Limestone transitions to a calcareous shale facies further into the Basin in Mississippi). The source of sediments for the Carter and Sanders sandstones appears to be the relatively stable cratonic margin of the Nashville Dome (i.e., from the north). Within the updip area of northwest Alabama (Lamar, Fayette and Pickens Counties), the Carter Sand is interpreted to consist of numerous lenticular marine bars oriented NW/SE (parallel to structural strike). Further southeast (into Pickens County), the sandstones thin into siltier lenses that probably represent a prodeltaic/distal facies equivalent. To the southwest, the strike-oriented marine bars continue into the Lee, Monroe and Lowndes County areas of northeast Mississippi. Moving further southwest into the Mississippi side of the Basin, the Carter-Sanders Sand interval expands somewhat, and the single marine bar facies observed in the updip area develops into a series of stacked bar sands that coalesce with the underlying Sanders Sand before grading laterally into a series of tight laminated siltstones. In Monroe County, two bar sand sequences - the upper "A" and the lower "B" - typify the Carter Sand sequence, with the thicker Carter "B" Sand frequently reaching a gross sand thickness in excess of 80 feet. Oil shows are very common in Carter Sand gas reservoirs, even those that produce only dry gas.

Petrophysically, the Carter Sand exhibits a porosity range of nil to 20% and a permeability range of nil to 200 millidarcies. In the past, the industry has typically utilized an 8% to 9% "productivity" cutoff for log crossplot porosity; it should be noted, however, that most density/neutron porosity logs that have been run in BWB wells used a limestone - not sandstone - lithology matrix when converting density to porosity, which in sandstones yields a porosity calculation that is generally 2% to 3% too optimistic (too high). Thus it appears the actual "productivity" cutoff for log crossplot porosity in the Carter Sand (as well as the other Mississippian sands in the Basin) is actually 6% to 7%. Induction log resistivities for producing reservoirs typically range from 40 ohm-meters to 200 ohm-meters or higher. The Microlog is a valuable tool in evaluating the prospectivity of a Carter sandstone reservoir; commercial completions typically require at least two feet of Microlog-implied permeability (separation). Small fracture stimulations (utilizing from 25,000 to 50,000 pounds of proppant) dramatically improve producibility, often resulting in ten-fold increases in daily rates of production. Although nearly all of the hydrocarbon production from Carter Sand reservoirs is methane, some oil reservoirs have also been discovered and developed, including the 6.6 MMBO North Blowhorn Creek Field, which has accounted for approximately 90% of the oil produced to date.

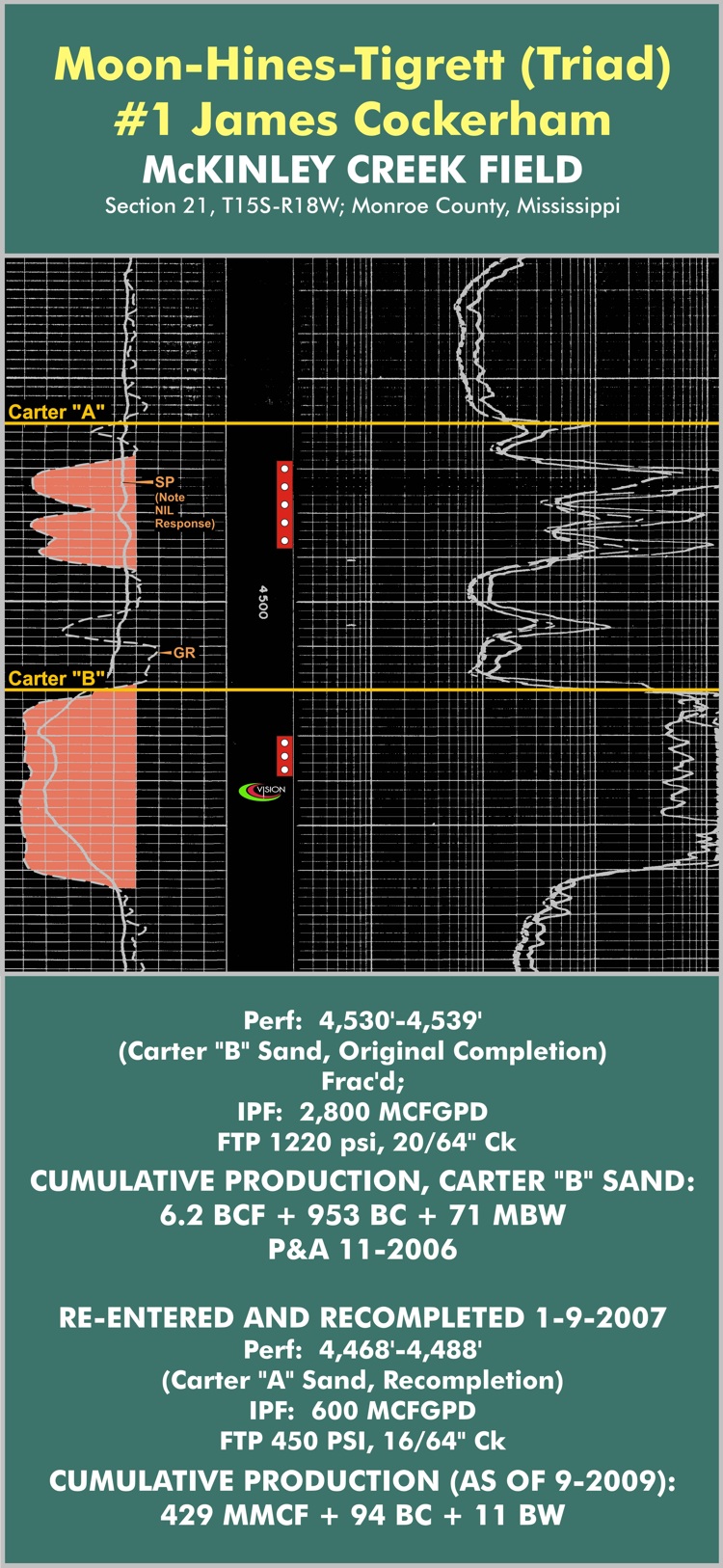

The SP (Spontaneous Potential) Curve is one log curve that should not be used to condemn a sandstone logged in the Carter Sand interval (or for that matter, any sandstone interval within the Mississippian in the BWB). Many prolific Carter Sand wells exhibit little or no SP Curve deflection on the correlation/induction log, suggesting a very silty or shaley composition; yet the Gamma Ray Curve will exhibit a clean sand profile across the same interval, as will the porosity log and the Microlog. Thus it is important to examine a complete log suite when evaluating a Mississippian sandstone in the BWB; relying on one-inch correlation logs can result in one walking away from a good commercial completion, as happened in 2007 when a large company plugged the #1 Cockerham (API #23095201080001) without testing a Carter "A" Sand that exhibited nil SP Curve deflection (all casing was left intact when it abandoned the well). Vision Exploration, having studied the porosity log for the well - which indicated good porosity and Gamma Ray deflection - recommended to its client that the plugged well be re-entered immediately and completed across the Carter "A" (an operation that cost approximately $60,000). Vision's client followed this recommendation and completed the well as a successful Carter "A" Sand completion - unstimulated - averaging 500-600 MCGGPD and paying out in less than 90 days. The five-inch induction log for that Cockerham well, across the Carter "A" and "B" Sand interval, is shown below; the Gamma Ray Curve has been digitally traced from the porosity log and added to the induction log by Vision to illustrate the SP/Gamma Ray curve dissimilarity.

In northern Lee and Itawamba Counties (north of the fault trend), an influx of fresh water from the Cretaceous / Carter Sand subcrop has invaded ("flushed") the Carter Sand, resulting in a highly resistive induction log profile that can be easily mistaken for the presence of hydrocarbons. It is thus prudent to examine sample logs and mudlogs for shows, and density/neutron logs for "gas effect", before concluding any induction log from that area exhibits a hydrocarbon response.